IMF SHOP ROASTERS

Using the same technology as IMF's industrial roasters, the IMF shop roaster's are ideal for cafes & boutique roasteries, especially where space is limited & the emissions are required by council to be treated (no smoke). The built in afterburner saves considerable installation cost as there is no separate unsightly afterburner to install. A specially designed combustion chamber that simultaneously heats the roaster & treats the emissions results in a minimum 30% saving in gas consumption compared with roasters fitted with separate afterburner. The Vortex & Equalizer technology ensures a consistent roast batch after batch.

The VORTEX system mixes ambient air into the hot airstream before it enters the roaster via an electronically operated modulating valve, so the air is already at the correct temperature before it enters the drum giving consistently uniform temperature of the hot airstream through the entire roasting process on every roast.

The EQUALIZER ensures the same volume of air enters into the roaster. This feature delivers equal volumes of hot air both inside and surrounding the perforated alloy drum surface, giving even heat distribution across the entire surface of the coffee beans, and eliminating any temperature fluctuations inside the drum. Temperature and air volumes can be adjusted according to the coffee blend or single origin via the PLC touch-screen.

Unlike conventional roasters that use a burner for the roaster and a separate burner (afterburner) to treat the emissions, IMF roasters use a specially designed combustion chamber that simultaneously heats the roaster & treats the emissions. As the coffee is roasted, the emissions leave the roaster via a steel duct into the burner chamber to incinerate the emissions. Some of the heat in the burner chamber, which would otherwise be released into the atmosphere, is instead re-circulated via a duct back into the roaster. Ambient air is mixed into the duct electronically to reduce the heat to the required temperature to heat the beans for roasting, and the cycle starts again. A minimum 30% reduction in gas consumption is achieved.

IMF Roasters are constructed using the highest grade materials. The mild steel drum gives uniform heat transfer at constant heat whether it is the first or last roast of the day. Built in Italy, IMF roasters and equipment are manufactured to exacting standards and worlds best practice.

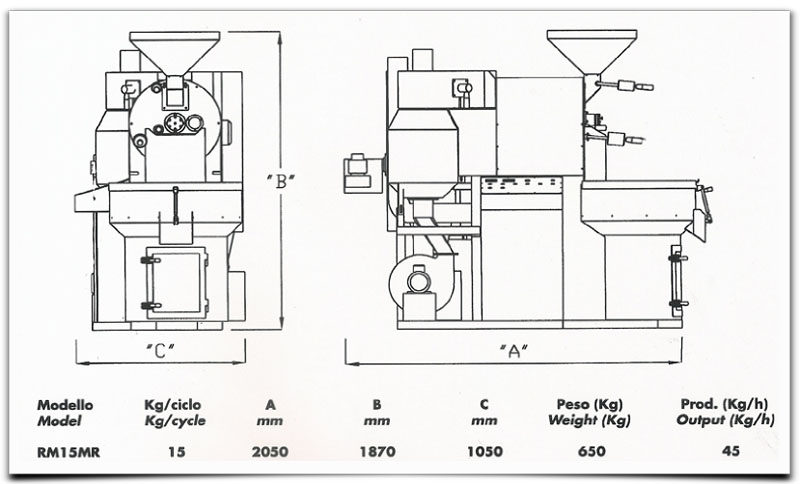

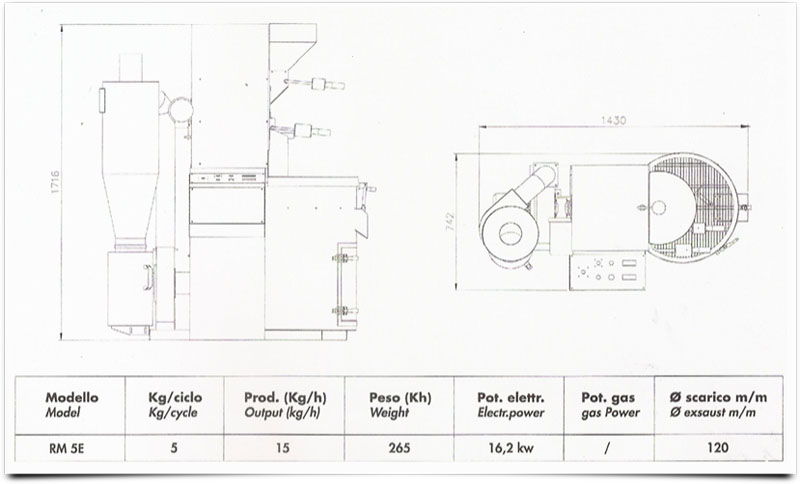

IMF Shop Roasters come in 5kg & 15kg sizes. Fully automatic, semi-automatic and manual models are available.